Table of Contents

Introduction: PLC Full form

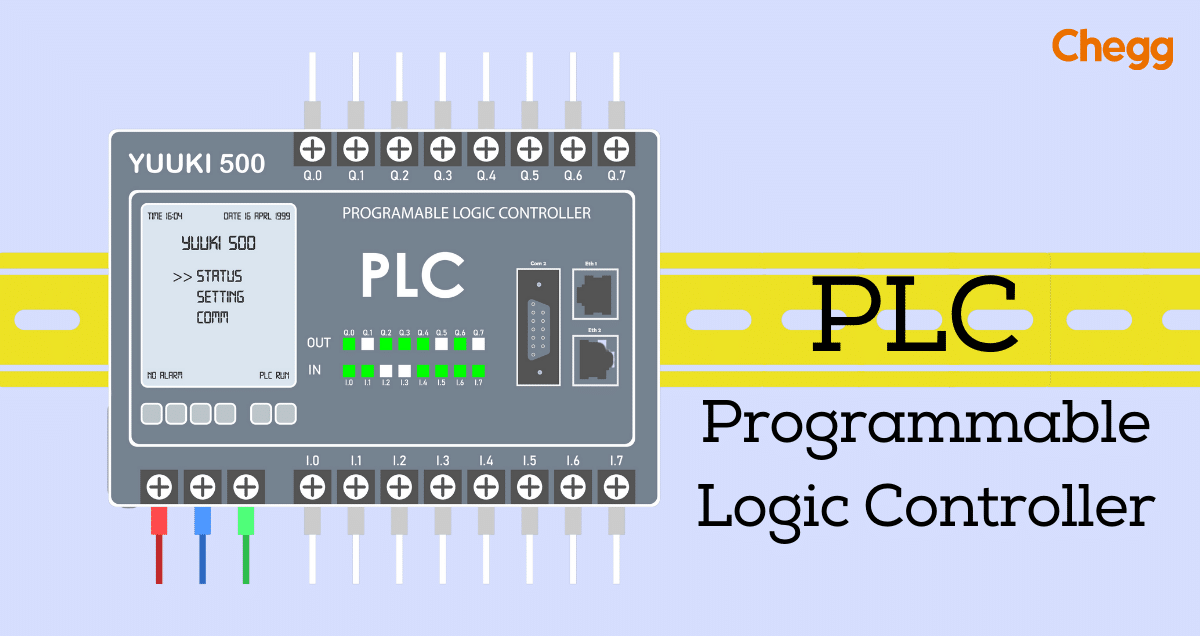

PLC full form is a Programmable Logic Controller, a special-purpose computer with no display, hard drive, or keyboard. It can control processes in industries like petroleum, steel, and automotive. A PLC is the workhorse of industrial automation. They are used in commercial or industrial appliances to control systems with minimal or no manual labor. PLCs have come a long way since their inception and have become crucial to modern industrial automation.

In this blog, we will explore the evolution of PLC technology and delve into its significance in industrial automation.

PLC History

Richard E. Dick Morley is the father of the Programmable Logic Controller, along with Dr. Odo Struger. They both worked with General Motors to develop a PLC that would significantly reduce the dependence on the relay system. Before the introduction of PLCs, the only way to control machines was through relay systems. Relays are electromagnetic switches to switch to higher loads. Relay systems were complex to manage. They had to be rewired to supply higher voltage. The major problem with the relay was that:

- They had to be hardwired separately.

- They had difficulty with troubleshooting.

- The wear and tear to the relays due to moving the parts frequently.

- If they had to be reconfigured, the wiring had to be changed.

- It also had a higher maintenance cost.

The very first model of PLC was the MODICON MODEL 084. Now it has revolutionized industrial automation, mainly used for performing repetitive tasks.

Working Principles

Every PLC has three parts: the input, the CPU, and the output.

- A program is created on a computer and downloaded to the PLC’s CPU.

- The switch needs to connect to the input to control a motor. Therefore, the motor needs to connect to the output.

- An electrical signal is sent to the programmed PLC when the switch is pressed.

- The input module of the PLC receives the signal and transfers it to the CPU for processing.

- The CPU processes the received data based on the program instructions.

- The processed data is transferred to the output module of the PLC.

- The output module converts the data into a raw electrical signal.

- To turn the motor on, the motor needs a raw electrical signal.

- Again, after pressing the switch, the same procedure occurs, but the motor turns off this time.

Components of a PLC system

The hardware and software components of PLC are as follows:

PLC hardware

Power Supply

For the supply, the AC mains need to connect to the power supply. Its output is a DC voltage, which is to supply power to modules attached to the PLC.

Input/Output Modules

Sensors, switches, transmitters, etc. are input devices. Output device includes motors, relays etc.

Processor

Processors include the CPU, which transfers the data from the input to the output module.

Programming device

Programming devices include external computers that make programs or codes for the PLC.

PLC Software

Programming languages

Various programming languages are used to program a PLC, like Ladder Logic, inspired by relay circuit diagrams. Another one is Structured Text, which is more complex and allows the creation of complex programs.

Human-machine interface (HMI)

They are used in industrial settings to control machines. HMI usually has a display with buttons or switches for input, then is read by the PLC, resulting in the output. Example: ATMs.

Applications of PLC

A PLC is used for repetitive tasks, which has increased the efficiency of the automotive industry. PLC full form itself explains the potential uses:

- Conveyor belt systems.

- Packaging and labeling.

- Bottle-filling automotive system.

- Escalator and elevator.

- Cement industries for mixing the proper quantity of raw materials and manufacturing the same.

- Fault or error detection.

- Traffic control system.

- Detection and alarm when a fire occurs.

- Car washing system.

- Switching on and off any application like light, fan, AC, etc.

Advantages of PLC

The most common advantages of using PLC are as follows:

- PLCs are extremely flexible, as entering or creating new programs without rewiring the entire circuit is easy.

- Unlike relay logic control, there is no need to hardwire the entire system.

- They are more compact and consume less plant or industry space.

- They are designed to perform at a higher speed and can obtain real-time solutions to the problem.

- They are extremely capable of troubleshooting any errors in the machine.

- They consume less power compared to a relay logic system.

Disadvantages of PLC

While PLCs offer numerous advantages in industrial automation, they also have some disadvantages:

- For an operator to maintain the PLC, they must be trained properly and efficiently to get the optimum usage out of the system.

- Regular maintenance checkups are required to ensure the system operates at its maximum capacity.

- Installing a PLC can be costly upfront, but it compensates through its high-functioning capabilities.

Future trends in PLC technology

The PLC technology could be integrated with other systems and devices. The technology could be designed to have a faster processor that would process the information in nanoseconds with a more added memory backup system. Like any technology, PLCs will become even more compact and smaller to use their capabilities efficiently. PLCs can integrate with the Internet of Things or IoT, allowing the exchange of data and further enabling advanced data analytics. It may have more security features like encryption so that only the designated operator cannot access it.

Other control systems vs PLC

Relay logic vs PLC

- Relay logic control is a method of creating electrical circuits using relays wired in a specific configuration. Whereas PLC is a specialized computer adapted to perform a certain specific function that it is programmed to execute.

- Relays work on analog signals, whereas PLC is digital.

- Relays do not have a memory backup, whereas PLC has memory to store its program.

DCS (Distributed control system) vs PLC

- PLC can control specific functions of a machine, whereas DCS overlooks the functioning of the entire plant.

- PLCs can execute their tasks at high speed, whereas DCS can perform functions in bulk or be able to perform heavy operations.

- PLCs have centralized controllers, whereas DCS needs no centralized controllers as its network is distributed throughout the plant.

SCADA (Supervisory Control and Data Acquisition) vs PLC

- PLC vs. SCADA (Supervisory Control and Data Acquisition)

- The main difference between PLC and SCADA is that the former is hardware, and the latter is software.

- PLC has only one function to perform for which it is programmed, whereas SCADA operates on a much wider scale.

- PLCs can perform their function without the SCADA system. On the other hand, SCADA acts as an interface between the operator and the PLC.

Learn more about some other full forms:

| HDD Full Form | USB Full Form | ALU Full Form |

| PCD Full Form | MCB Full Form | SIM Full Form |

| CRT Full Form | LCD Full Form | LED Full Form |

Conclusion

Like every technology ever created, PLCs have transformed the technological landscape. It has increased flexibility and reliability and, more importantly, decreased the use of manual labor, which has, in turn, increased efficiency. As the technological environment is still evolving, PLCs will evolve in the future, perform even more complex tasks, and will be easier to integrate with artificial intelligence.

PLC Full Form: FAQs

What is PLC full form?

PLC full form is ‘Programmable Logic Controller’. It is a digital computer-based control system. It can automate and control various industrial processes and machinery.

What are the main components of a PLC system?

The PLC system includes the Central Processing Unit (CPU), input modules, output modules, power supply, and communication ports.

Is it possible to expand or modify a PLC system?

Yes, it is possible to expand or modify a PLC system by adding or changing hardware modules and updating the control program.

What are the three types of PLC?

The three main types of PLC are:

1. Modular PLCs

2. Compact PLCs

3. Rack-mounted PLCs

What are some common applications of PLCs?

PLCs are widely used in various industries for assembly lines, manufacturing processes, and building automation. They are also used in water treatment, energy management, automotive production, and more.

Got a question on this topic?